In the production line, or off-line, it is often necessary to trim finished products, or cut them lengthwise into strips and transverse to the length of the desired size.

To perform these tasks you can use very different cutting technologies:

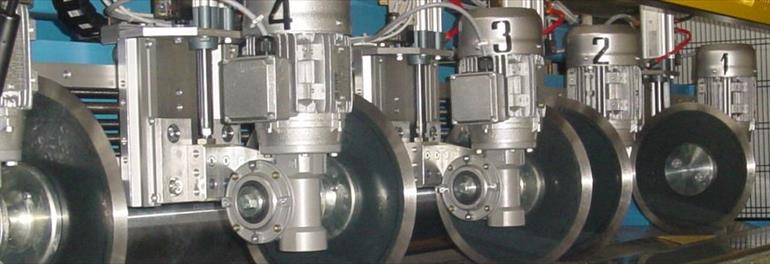

The blades for cutting the material along the production flow are called longitudinal cuts. They can be only two for trims cutting or multiple if you want to cut the materials in strips. Their positioning can be fixed or variable, and their regulation can be manual or automatic. The cut which takes place perpendicularly to the flow of production is called transverse cut. This can be performed automatically at predetermined measures (via measuring with metric wheel or photocell) and it is usually fixed. Besides, to cut rigid panels it is possible to set flying shear. The most appropriate cutting technology will be chosen according to the type of material (thickness, density and other characteristics).